VEGA Golf Club Review - What are they? - Explained

As the story goes, 100 years ago the first golf course was built Kobe, Japan. The area surrounding this golf course has been well established as a metal works area, forging samurai swords, a skill that has been passed down the generations. VEGA Golf is accredited for producing the first forged cavity back iron, allowing more golfers of more skill levels to appreciate the fine craftsman ship and feel of forged clubs. No longer are forged clubs only available in muscle-back designs.

Today, VEGA Golf has many models to choose from, offering a full line for the full spectrum of golfers. Low-handicap golfers have two options in the VM (VEGA Muscle) series of irons, a small muscle-back blade iron that screams "I am a player!" while in the bag. You can definitely send a message to your playing partners with the VEGA VM-02 and VM-01 irons. Meanwhile, high-handicap have the VEGA VC (VEGA Cavity) series of irons, a cavity back that offers more forgiveness on miss-hits. These irons in the bag says "I appreciate high quality goods". Models offered are the VC-05 (most forgiving), VC-03, VC-02 and VC-01 irons. Between the VM and VC models, VEGA offers a very compelling set to possible combo, designing a set make-up with VC's as a golfers long irons and VM's in the short irons. Or even just keeping all VC's, but combo'ing VC-03 in long irons and VC-02 or VC-01 in the short irons. So many possibilities, VEGA has a really nice cohesive offering to get creative and design set make-up that fits many golfers and their game.

There are two outliers in the VEGA line that are not part of the VM or VC irons, the VDC-01 (VEGA Dual-Cavity) and the MIZAR.

The VDC-01 (pictured left) is among the most beautiful irons that we at Spargo Golf have had the pleasure of building. The VDC-01 is defined as a low flight, low offset club-head with the performance of a muscle iron but forgiveness of a cavity-back. The perimeter weighting allows for less muscle behind the club-face, giving a softer feel and moving the CG higher on the club-face. The VEGA VDC-01 is described as having a more square toe when compared to the VC irons and less offset to appeal to low-handicap golfers still wanting a lower ball flight.

The VDC-01 (pictured left) is among the most beautiful irons that we at Spargo Golf have had the pleasure of building. The VDC-01 is defined as a low flight, low offset club-head with the performance of a muscle iron but forgiveness of a cavity-back. The perimeter weighting allows for less muscle behind the club-face, giving a softer feel and moving the CG higher on the club-face. The VEGA VDC-01 is described as having a more square toe when compared to the VC irons and less offset to appeal to low-handicap golfers still wanting a lower ball flight.

The MIZAR (pictured right) is completely different from all the other irons, its in a world of its own. The MIZAR is a two piece iron. The iron face is a 3.5mm thick Carpenters steel maraging face provides forgiveness and uniform feel, coupled with a forged main body from s25c carbon steel. Writing this blog got me wanting to hit this club, we have it in our studio built with an OBAN steel R+ flex shaft, which is perfect for me. I grabbed some range balls and gave it a few swings... My thoughts? The MIZAR is a really, really cool club. Amazing feel, easy to handle, picked a target and just hit it. When you're in the market for a new set of irons, this needs to be on your list to check out...

The MIZAR (pictured right) is completely different from all the other irons, its in a world of its own. The MIZAR is a two piece iron. The iron face is a 3.5mm thick Carpenters steel maraging face provides forgiveness and uniform feel, coupled with a forged main body from s25c carbon steel. Writing this blog got me wanting to hit this club, we have it in our studio built with an OBAN steel R+ flex shaft, which is perfect for me. I grabbed some range balls and gave it a few swings... My thoughts? The MIZAR is a really, really cool club. Amazing feel, easy to handle, picked a target and just hit it. When you're in the market for a new set of irons, this needs to be on your list to check out...

Uniquely, the MIZAR offers progressive tungsten weighting, shorter irons locate the tungsten near the toe, and longer irons toward the heel. Doing this helps square the club-face at impact for straighter, longer shots. The tungsten helps lower the CG for higher launch, low spin flight characteristics. Overall, very neat... The VEGA MIZAR is officially on my wish-list.

Overall, VEGA Golf has got some good stuff, the bread and butter of the company is the forging process (see below). VEGA has some great designed irons that are also perfectly manufactured too. A superior designed iron means nothing if its not executed in production. Obviously, the best thing you can do is get fit for VEGA irons, but if you already know what you want, you can order below ;)

Forging Process

Ten stages of highly scrutinized quality control from forged steel billets to paint-fill, the stages are explained in detail below.

Stage 1

Already grain forged, S25C mild steel iron rods (anywhere from 6' to 10' long) are cut into shorter 5"-6" billets. These cut billets are then heated to 1200ºc (or 2,192ºf) till they are glowing red and molten to begin the shaping process.

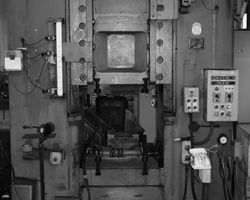

Stage 2

Pictured is the forging hammer. Each iron has its own set of dies (top and bottom) strike the billet into shape. The machine drops down on the molten billet to a specific amount of force, striking and forcing the iron into an approximate shape of the iron-head.

Stage 3

Still in the drop-forge machine, the hammer takes a few softer hits into the still hot billet to refine the shape of the iron even more, and last strike to ensure the club-face is perfectly flat.

Stage 4

The excess metal that squeezed out the edges of the die is now trimmed off, revealing the shape of the iron for the first time and can now get pressed the iron model and grooves. The grooves are not cut but rather pressed into the club-face, which keeps the forging structure of the iron pure. Also note, the hosel was forged with the rest of the club-head, rather than welding the hosel on later, which gives the VEGA iron a stronger construction and uniform feel.

Stage 5

A craftsman reams a .355" Taper shape I.D. into the hosel to accept a shaft from a golfers fitting. If needing a .370" Parallel I.D., Spargo Golf does on site when getting built by our recognized Top 10 Worldwide club-builder, Tom Spargo.

Stage 6

A new specialized craftsman hand grinds and polishes the the VEGA iron heads to their perfect shape and weight.

Stage 7

The heads are then given a further polishing in the polishing barrel.

Stage 8

The heads are then masked and the faces hand sand blasted.

Stage 9

VEGA iron heads are now passed through the chrome plating process. There are numerous types of finish available (Raw, Satin and Charcoal).

Stage 10

The final quality control is carried out by a highly specialized craftsman who check the VEGA irons for loft, lie, weight and lastly any imperfection. Only the perfect iron heads are passed through this final stage. Lastly, the paint-fill is added to the irons VEGA logo, model number and iron number on the sole.

What are your thoughts about VEGA Golf or this blog? COMMENT BELOW!

Leave a comment

Comments will be approved before showing up.

Also in Blog

PING G410 Hybrid vs G410 (XR) Crossover - Review

How To Practice Golf And The Shots You Need To Learn

“The definition of insanity is doing the same thing over and over again, but expecting different results”

- Albert Einstein